Intelligent Power Distribution Unit

Newsunn intelligent power distribution unit (iPDU) is designed primarily to remotely monitor and manage power in data centers, server rooms, and other mission-critical facilities, allowing data center administrators to monitor power usage, track environmental conditions, and receive alerts in the event of power outages or other issues. It is a critical component of modern data center infrastructure, providing advanced power management and monitoring capabilities that help ensure reliable and efficient data center operation.

Intelligent PDUs,also called smart PDUs are advanced power distribution units that offer a range of benefits for data center optimization and energy efficiency. With outlet-level metering, remote power monitoring, and other advanced features, intelligent PDUs enable accurate and real-time monitoring of power consumption, allowing data center operators to manage power distribution more efficiently and effectively. This level of PDU monitoring and management is crucial for ensuring optimal performance and reliability in data centers, as it enables operators to identify and resolve power consumption issues quickly and easily.

By providing real-time data on power usage, intelligent PDUs also help to improve energy efficiency in data centers. This is achieved by enabling operators to identify areas where power usage can be reduced, such as by consolidating workloads or shutting down unused equipment. This data also enables operators to track power consumption trends over time, which can inform decisions about future capacity planning and energy optimization.

In addition to PDU monitoring and management, intelligent PDUs can be integrated with other data center management systems, enabling comprehensive data center infrastructure management. This integration allows for centralized monitoring and control of power distribution and consumption, reducing the risk of downtime and improving overall facility management.

Overall, it is a trend to install the intelligent PDU in data centers.

Key Features

· Web-Based Management

A full-featured web-based GUI provides an intuitive and accessible way to manage their Intelligent PDUs, monitor power usage, and optimize energy efficiency in their data centers or server rooms from any locally connected PC.

· Configurable Alerts

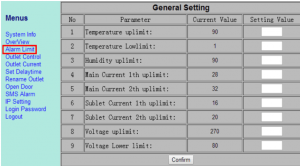

Audible and E-Mail,SMS alerts can be configured to alert users to impending power overloads or temperature problems (with optional temperature and humidity sensor)- helping users to protect their A/V equipment against failure.

· Temperature and Humididty Monitoring

The Temperature and Humidity Sensor (Sold separately) allows automated alerts or power-off of equipment if ambient temperatures or humidity rise above a user-defined threshold - protecting users’ equipment from failure.

In addition, there are door sensor, smog sensor and water logging sensor for option.

Major Functions

Newsunn intelligent PDU has Four models in terms of metering and switching: 1. Total metering; 2. Total switching; 3. Outlet metering; 4. Outlet switching.

1. Total metering

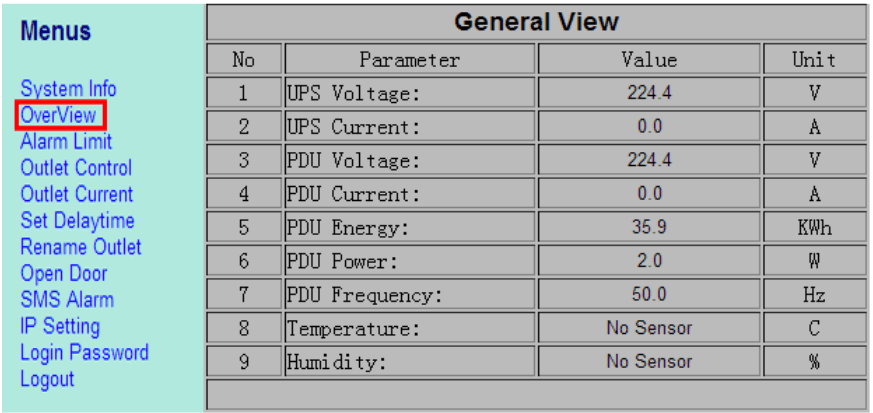

Remote metering PDU function include: total current, voltage, total power, total electric energy, temperature, humidity, smog, water logging, entrance guard etc.

2. Total switching

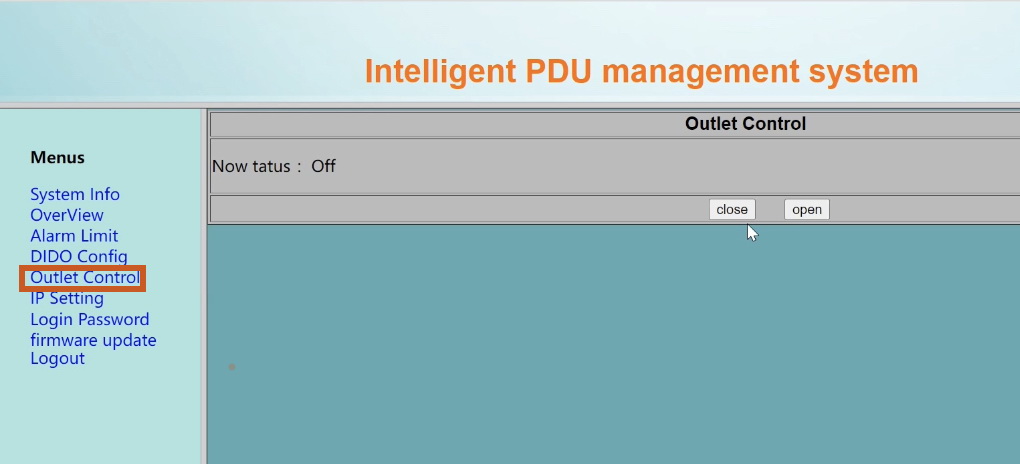

Control the total circuit switch by a single module.

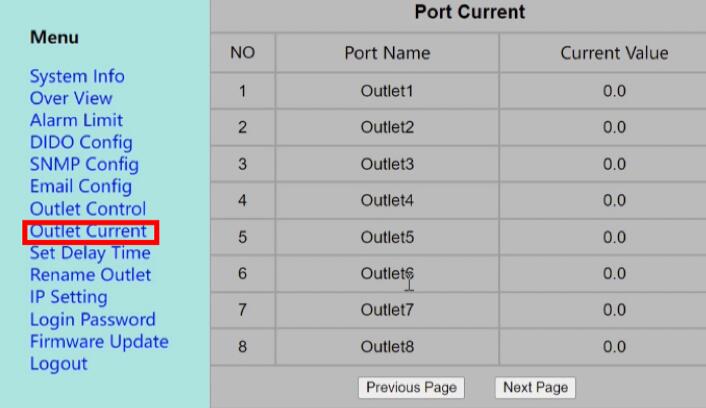

3. Remote Outlet-by-Outlet metering

Monitor the current of each outlet.

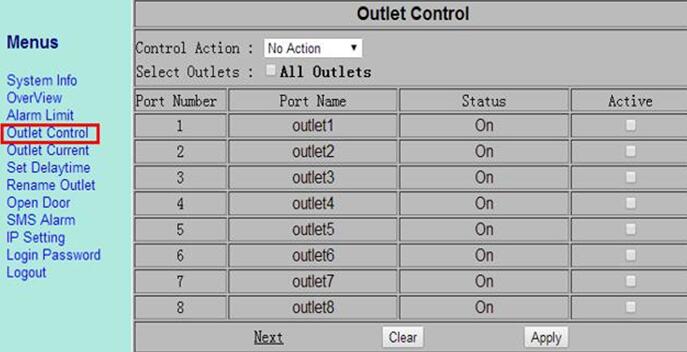

4. Remote Outlet-by-Outlet switching

Remote outlet swithching PDU includes the function of control each outlet switch, set each outlet delay time, renaming outlet, etc.

Newsunn intelligent PDU includes Four models based on metering and switching functions.

Type A: Total metering + Total switching + Individual outlet metering + Individual outlet switching

Type B: Total metering + Total switching

Type C: Total metering + Individual outlet metering

Type D: Total metering

|

Main function |

Technical instruction |

Function Models |

|||

|

A |

B |

C |

D |

||

|

Metering |

Total load current |

● |

● |

● |

● |

|

Load current of each outlet |

● |

● |

|||

|

On/Off state of each outlet |

● |

● |

|||

|

Total power(kw) |

● |

● |

● |

● |

|

|

Total energy consumption(kwh) |

● |

● |

● |

● |

|

|

Work voltage |

● |

● |

● |

● |

|

|

Frequency |

● |

● |

● |

● |

|

|

Temperature/Humidity |

● |

● |

● |

● |

|

|

Smog sensor |

● |

● |

● |

● |

|

|

Door sensor |

● |

● |

● |

● |

|

|

Water logging sensor |

● |

● |

● |

● |

|

|

Switching |

On/off of the power |

● |

● |

||

|

On/off of each outlet |

● |

||||

|

Set the interval time of outlets’ sequential on/off |

● |

||||

|

Set the on/off time of each outlet |

● |

||||

|

Set limiting value to alarm |

The limiting range of total load current |

● |

● |

● |

● |

|

The limiting range of load current of each outlet |

● |

● |

|||

|

The limiting range of the work voltage |

● |

● |

● |

● |

|

|

The limiting range of temperature and humidity |

● |

● |

● |

● |

|

|

System automatic alarm |

The total load current exceeds the limiting value |

● |

● |

● |

● |

|

The load current of each outlet exceeds the limiting value |

● |

● |

● |

● |

|

|

Temperature/Humidity exceeds the limiting value |

● |

● |

● |

● |

|

|

Smog |

● |

● |

● |

● |

|

|

Water-logging |

● |

● |

● |

● |

|

|

Door opening |

● |

● |

● |

● |

|

Controlling module

Newsunn designs a user-friendly, intuitive, and accessible interface of the controlling module including:

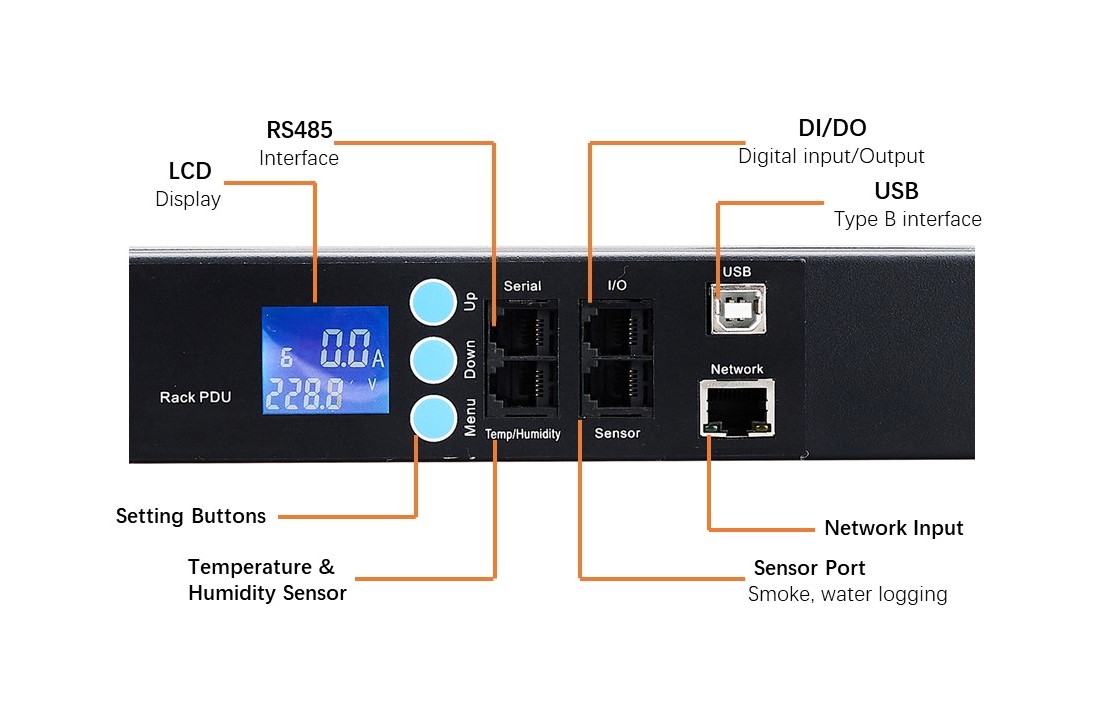

LCD Display: provides real-time information on the status of the PDU and its connected devices, showing power usage, outlet status, environmental conditions, and other relevant information.

Buttons: UP and DOWN buttons allow page up and down to view each loop current, IP address, baud rate, device ID, etc. MENU button is for parameter setting.

Network Connectivity: Ethernet ports, that allows administrators to remotely monitor and manage the PDU using a web-based management interface or command-line interface.

Communication interfaces: I/O port (Digital value input/output), RS485 port (Modbus protocol); USB port for console access; Temp/Humidity port; Senor Port (for smoke and water).

Operation Demo---- So Easy!!!

PDU Specification

|

Item |

Parameter |

|

|

Input |

Input Type |

AC 1-phase, AC 3-phase,240VDC,380VDC |

|

Input Mode |

3meter Power cord with specified plug |

|

|

Input Voltage Range |

100-277VAC/312VAC-418VAC/100VDC-240VDC/-43VDC- -56VDC |

|

|

AC frequency |

50/60Hz |

|

|

Total load current |

63A at maximum |

|

|

Output |

Output voltage rating |

220 VAC,250VAC,380VAC,-48VDC,240VDC,336VDC |

|

Output frequency |

50 /60Hz |

|

|

Output standard |

6x IEC C13. Optional C19, German standard, UK standard, American standard, industrial sockets IEC 60309. Etc. |

|

|

Output quantity |

48 outlets at maximum |

|

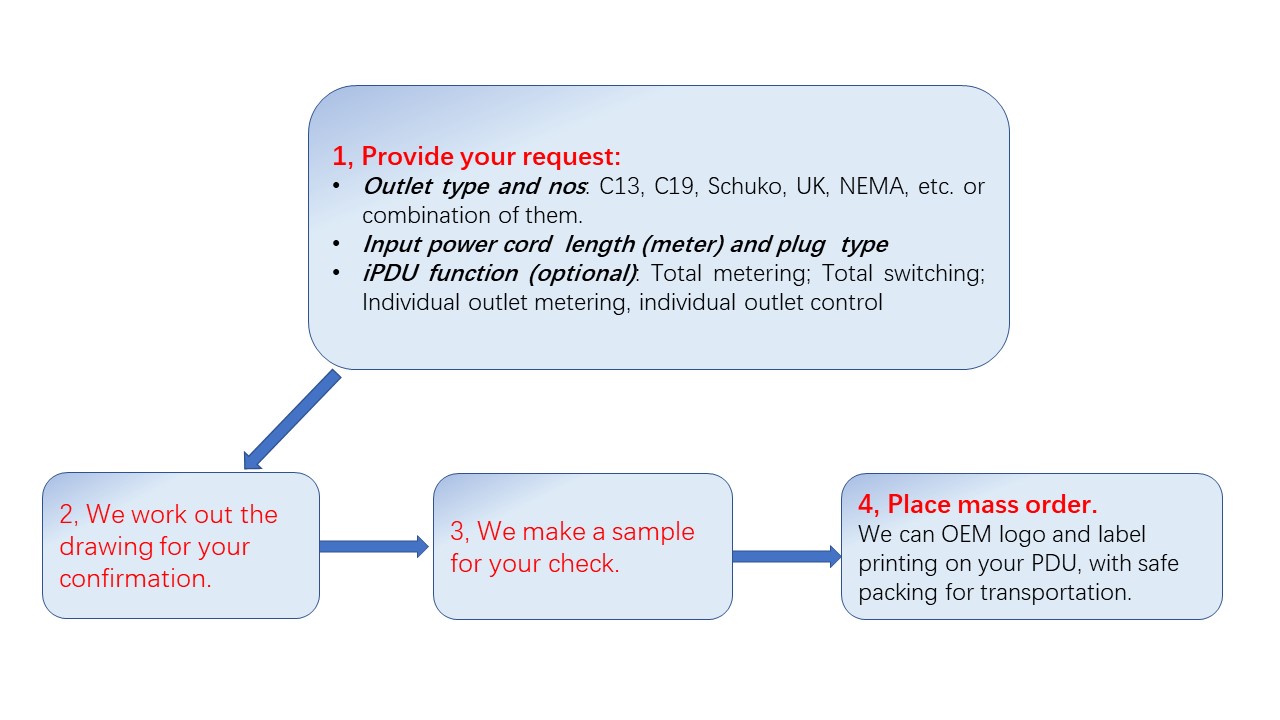

OEM & Customization

For example, you can describe your demand as below:

- IP management vertical PDU (total metering), Single phase, 36xC13 + 6xC19, 1x32A, MCB, 7.2 kW, 3 m power cord with IEC60309 plug;

- Intelligent 3-phase PDU (total and individual metering), 36xC13 + 6xC19, 3x16A, MCB3, 11 kW, 3 m power cord with IEC60309 plug;

- 19inch 1U intelligent PDU ( total and outlet metering and switching), 6xC13, 3 m power cord with Schuko plug;

- Vertical basic C13 3-phase PDU, 6xC19+36xC13, with IEC60309 380V/16A plug;

- 19inch 1U rack mount PDU, 16A, 250V, 8x Schuko outlets and 1.8m embedded power cord(1.5m2), with master switch and circuit breaker;

- 19inch 1U C19 PDU, 10A, 250V, 8x C13, C14 input socket, switch and overload protector;

- 19” 1U C13 lockable PDU, 10A/250V, 8xC13 with lock, switch and overload protector, embedded power cord with Schuko plug 3.0 m;

- Rack mount UK type PDU, 13A, 250V, 8xUK outlets, with a master switch, and 3m embedded power cord(1.5m2);

- 19" network cabinet 1U NEMA PDU, 15A, 250V, 8xNEMA outlets, with a master switch, and 3m embedded power cord(1.5m2)

Quality Control

♦ Patent and Certification

QC procedure

A. Visual Inspection: to ensure that the PDU's exterior is free from any physical defects, scratches, or damages, and also verifies that all necessary labels, markings, and safety instructions are present and legible.

B. Electrical safety testing: to ensure that the PDU is electrically safe to use, including

•Hi-pot test: 2000V high voltage test ensures the creepage distance of the product and prevents potential cable damage.

•Ground/insulation resistance test: ensures the ground resistance in line with safety regulations, to ensure absolute insulation between the ground wire and the poles.

•Aging test: 48-hour online aging test to ensure zero failure of products delivered to customers.

•Load test: 120%

C. Function testing: to ensure that all the PDU's features, such as outlets, circuit breakers, and switches, and remote control function are working correctly.